Latest Posts

Production Line for One of the USB Drive Chip — PCBA

USB Drive Production Line – PCBA Part

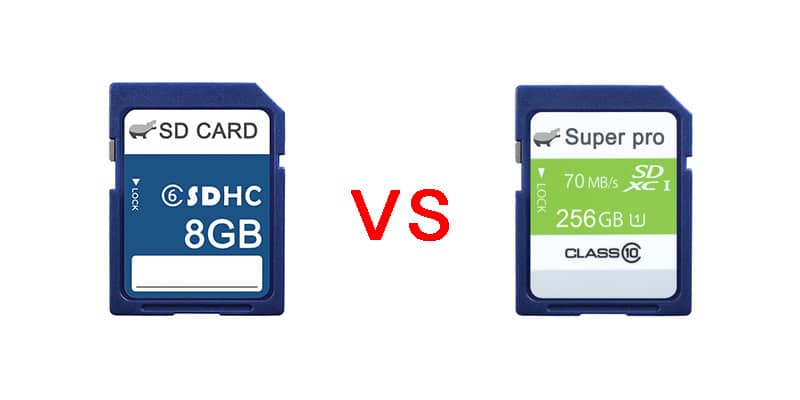

Wholesale USB flash drive is the popular external storage for daily use. People use it to load varies content such as movie, music, files, pictures and the other info. To meet different demands of diverse devices, the USB flash drive has varies capacity, ranging from 128mb USB flash drive bulk to 1TB USB stick, furthermore it has USB 2.0 and USB 3.0 to provide different transferring speed. The specification for bulk USB flash drive is very simple, the above two parameters are the main ones. It is not like bulk Micro SD cards having so many speed specifications, as USB drive is mainly working with computer, and then it is mainly designing for PC. The only complex part for USB flash drive is the shell, as the attractive point is the outside looking, the shell will bring extra scores for USB selling.

What’s the inside chip for USB flash drive?

Besides all sorts of USB shells, the key for one USB flash drive is the inside chip. How is the chip look like? What kind chips are using for USB flash drive? Let’s disclose this part step by step. The looking of these two chips is as below image, we call it UDP and PCBA. PCBA is the earliest version of USB chip; also it is the cheaper one. It has varies size to follow the shell size, so it is very flexible for USB shell. Refer to the UDP, it is upgraded version of PCBA, the difference between them is size, packaging way and parameter. In fact, UDP can do anti-water, anti-dust, anti-shake and anti-drop; the cost of it is comparatively higher, meanwhile the performance of it is more stable. The USB flash drive with UDP inside is usually used for tiny shell.

What’s the suitable chip for wholesale USB flash drive?

Both chips are widely used for USB flash drive, although PCBA is not as good as UDP, it still has the market. As if you go for low cost and simple design, PCBA chip is the best choice. For example, if we take USB flash drives as exhibition gifts, all of them are free for our clients, and then the cost is the priority for the consideration. Whereas if you need USB flash drive for business promotion, and need it to load important data for the company, the stability of this USB flash drive is very important, if so we will recommend you use the USB with UDP inside. Therefore, Hero has his own place.

How does the production for PCBA chip?

We have introduced the chips for the USB flash drive, then how to make them will be the next topic. To meet the fast delivery and high quality, all these chips are made by machine, the only thing we do is to input correct setting for the production. Video for the PCBA production line

This video is MRT PCBA production line; all the steps are performed by machine. It is the production line for USB PCBA. With Machine hands, the production ability can reaches 10,000pcs per day. Also the failure rate will be lower than 2 out of 1000, it is the startup for the production of finished USB Flash Drive.

Leave a comment