Latest Posts

Traditional storage technology facing challenges pushes the emergence of new one

Challenges Faced by Traditional Memory Chips

Memory chips have a manufacturing process that is relatively straightforward. This allows for the rapid replication of memory cells, which has been a significant factor in the quick improvement of yields within advanced process technologies. Historically, memory chips have been pioneers in adopting new manufacturing techniques.

As advanced process technology has entered the 65 – nm era, many leading manufacturers have gained enough experience. This enables them to skip memory verification and directly apply advanced processes to logical products.

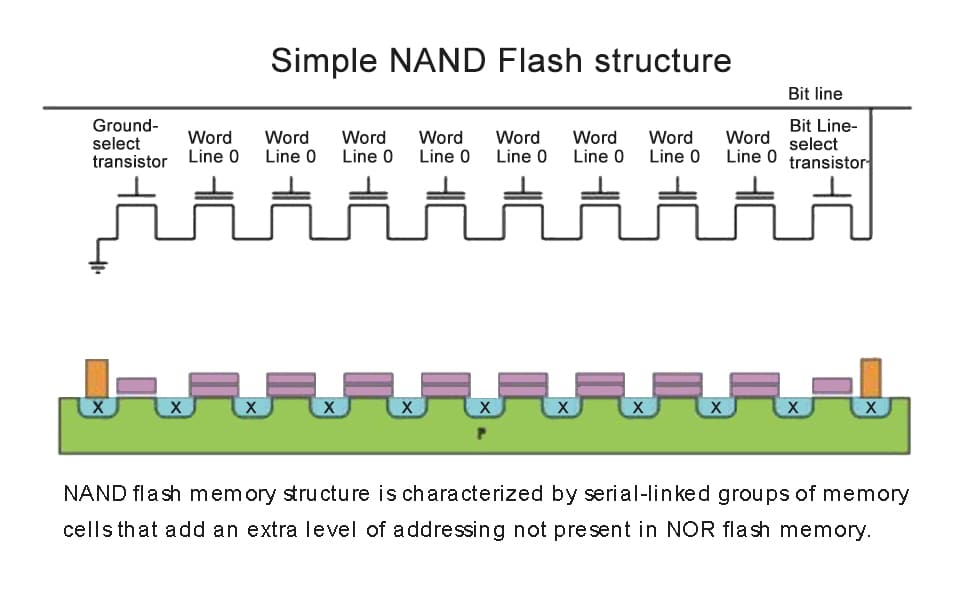

With the rise of AI, the Internet of Things, and other fields, big data applications are becoming more and more widespread. These emerging fields continuously drive the demand for memory to keep up with advanced processes. Currently, while major memory card manufacturers are upgrading to the 20nm process, traditional memories like DRAM, bulk micro SD memory cards, NAND flash, and SRAM still dominate the market.

The Development History and Features of MRAM Technology

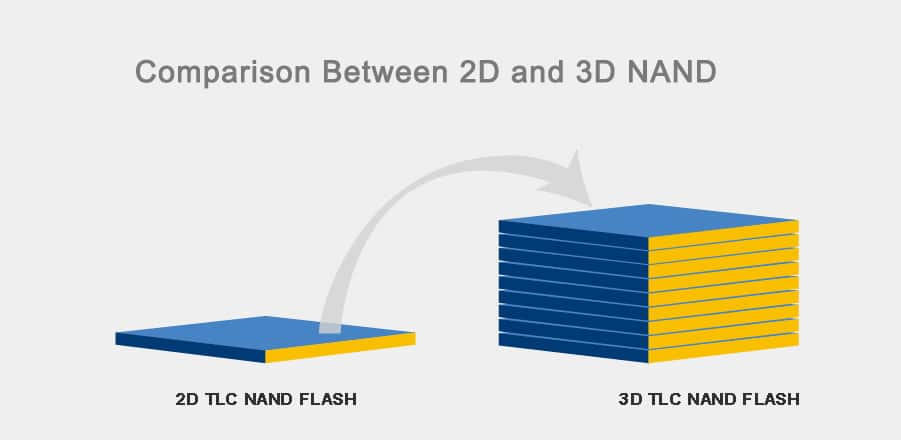

In this transition period, traditional storage technologies face numerous challenges. For instance, DRAM with its continuously miniaturized cell designs needs multi – pattern technology and ultimately EUV lithography for mass production. However, EUV is not yet scalable for large – scale applications. Similarly, planar NAND has moved to a vertical orientation, leading to the popularization of 3D NAND technology in the market.

Traditional storage technologies such as bulk SD cards are encountering challenges, but these challenges are also giving rise to new technologies like MRAM. MRAM combines the high – speed read/write performance of SRAM with the high integration of DRAM and offers virtually unlimited write cycles. Essentially, MRAM merges memory density with SRAM speed while being non – volatile and highly efficient.

- 1984: Discovery of the GMR effect by Albert Fert and Peter Grünberg.

- Mid – 1980s: Belief that MRAM could become the dominant or universal memory.

- 1996: Introduction of the spin transfer torque concept.

- 1997: Motorola develops a 256Kb MRAM test chip.

- 2002: Motorola awarded a patent for Toggle MRAM (first generation).

- 2004: Motorola spins off its semiconductor business to form Freescale Semiconductor.

- July 2006: Freescale sells the world’s first commercial MRAM chip at $25 with 4M bits.

- 2005: Renesas and Grandis develop a 65nm SST – MRAM.

- 2016: GigaDevice invests in Everspin, and Chinese institutions prepare an 80nm STT – MRAM device.

- 2018: Samsung announces plans to start STT – MRAM mass production.

| Company | Contributions to STT – MRAM |

|---|---|

| Everspin Technologies | Developed Toggle MRAM and continues to innovate in MRAM solutions. |

| Global Foundries | Collaborates on manufacturing advanced MRAM chips at various nodes. |

| Samsung | Produced commercial MRAM products and invests in scaling MRAM technology. |

| IBM | Conducts research and development, including demonstrations with Infineon. |

| Infineon | Participates in collaborative projects to develop MRAM technologies. |

Challenges and Future Prospects of STT – MRAM

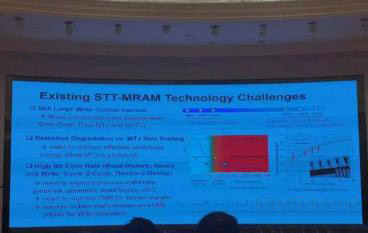

Despite its advantages, STT -MRAM faces challenges such as severe process variations and thermal fluctuations as technology scales down, impacting performance and stability. Thus, commercial applications remain a long – term endeavor.

Structurally, STT -MRAM stores data through Magnetic Tunnel Junctions (MTJs), which consist of two ferromagnetic layers and a non – magnetic isolation layer. Writing data requires a large current to generate a magnetic field, reversing the MTJ free layer’s magnetic moment. As storage cells shrink, larger currents are needed, increasing power consumption and slowing write speeds.

At CSTIC 2019, experts highlighted that current STT – MRAM challenges focus on balancing large write currents, MTJ scaling, and reducing bit error rates.

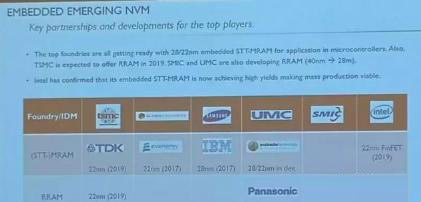

Challenges represent opportunities, and STT -MRAM remains attractive to major manufacturers. Companies like Everspin Technologies, Global Foundries, Samsung, IBM, and others have made significant strides in MRAM development and commercialization. Recent advancements indicate that STT – MRAM is poised for broader adoption, although it may coexist with traditional memory technologies like NOR flash for the foreseeable future.

In summary, while traditional storage technologies face hurdles, innovations like STT – MRAM offer promising solutions. Ongoing research and development efforts across the industry are expected to drive the evolution and adoption of these advanced memory technologies.

Leave a comment